Process Cooling

Manufactured for efficient heat transfer

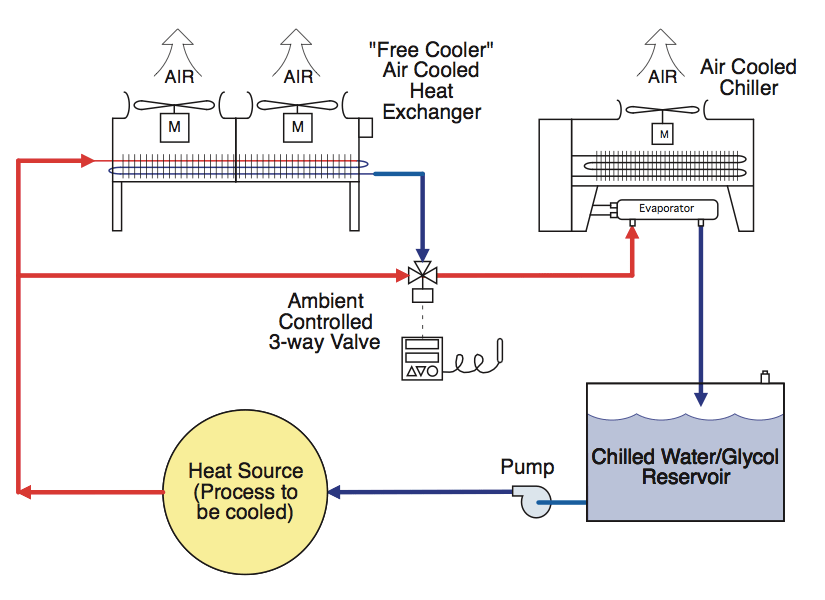

The Process Cooling industry is designed for heat processing and removing large amounts of heat from a space, which is commonly done with a chiller system or the removal of heat from industrial fluids using Levitor Fluid Coolers / commonly known as “Dry Coolers”.

A chiller normally has a mechanical compression device that converts energy into compressed refrigerant by using some type of compressor (Condensing Unit). The compressed refrigerant is piped to an air-cooled condenser (Levitor) that rejects the heat from the refrigerant to the atmosphere or some type of liquid coolant load where the heat is transferred to the coolant in the load heat exchanger and then returns to the evaporator to repeat the cycle.

Facilities we work with

- Plastics: Injection Molding, Blow Molding, Extrusion

- Chemical & Petrochemical Process Systems

- Refineries: Ethanol, Biodiesel, Gasoline

- Pharmaceutical

- Automotive: Plastics, Laser, Coolant

- Metal Working: Laser, Stamping, Welding, Hydroforming

- Paint Lines

- Bottling Plants

- Power Generation

- Laser Welding

The process